附件下载,需登录可以查看贴内更多信息

您需要 登录 才可以下载或查看,没有账号?立即注册

x

Pou PLC: A Reliable Solution for Industrial Automation and Control

Introduction

In today's industrial landscape, automation and control systems play a crucial role in optimizing processes and improving overall efficiency. Among the various options available, Pou Programmable Logic Controllers (PLC) stand out as a reliable solution for managing complex tasks in industrial settings. This article aims to delve into the features and benefits of Pou PLCs, highlighting their importance in the field of electrical engineering and automation.

Section 1: Understanding Pou PLCs

1.1 What is a Programmable Logic Controller (PLC)?

A PLC is a specialized computerized device used to control and monitor a wide range of industrial processes. It is designed to withstand harsh environmental conditions and to provide reliable control over machinery and equipment.

1.2 The Evolution of Pou PLC

Pou PLC is a leading brand in the field of industrial automation. With a rich history spanning several decades, Pou has continuously evolved its PLC offerings to meet the growing demands of the market. From small-scale control systems to advanced distributed control systems, Pou PLCs have proven their reliability and versatility.

Section 2: Key Features of Pou PLCs

2.1 Robust Construction and Durability

Pou PLCs are built to withstand extreme temperatures, vibration, humidity, and dust, making them ideal for deployment in challenging industrial environments. Their rugged construction ensures long-lasting performance and minimal downtime.

2.2 Versatile Communication Capabilities

Pou PLCs offer multiple communication options, including Ethernet, serial ports, and fieldbus protocols such as Profibus and Modbus. This enables seamless integration with various devices and systems, enabling effective data exchange and control over the entire industrial network.

2.3 Scalability and Flexibility

Pou PLCs come in different sizes and capacities, ranging from compact models suitable for small-scale applications to high-performance units capable of handling large-scale automation tasks. Additionally, their modular design allows for easy expansion and customization, ensuring adaptability to evolving industrial requirements.

Section 3: Application Areas of Pou PLCs

3.1 Process Control and Monitoring

Pou PLCs excel in process automation, offering precise control over variables such as temperature, pressure, flow rate, and level. They enable real-time monitoring of critical parameters, allowing engineers to optimize production processes and ensure product quality.

3.2 Machine Control

Pou PLCs play a vital role in controlling and coordinating various machinery, including motors, pumps, valves, and conveyor systems. Their high-speed processing capabilities enable efficient execution of complex control algorithms, providing precise and synchronized operation of interconnected equipment.

3.3 Safety Systems

Safety is a paramount concern in industrial settings. Pou PLCs support the integration of safety systems, enabling the implementation of emergency shutdowns, safety interlocks, and alarm systems. This ensures the protection of personnel and minimizes the risk of accidents.

Section 4: Programming and Development Environment

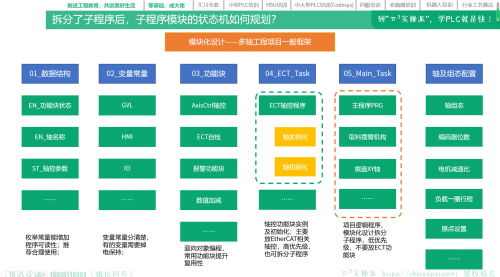

4.1 Pou PLC Programming Languages

Pou PLCs support multiple programming languages such as Ladder Diagram (LD), Function Block Diagram (FBD), Structured Text (ST), and Sequential Function Chart (SFC). This allows engineers to choose the most suitable programming approach based on their familiarity and project requirements.

4.2 Development Tools and Simulation

Pou provides comprehensive development tools for PLC programming, including software packages with intuitive user interfaces. These tools facilitate program development, debugging, and simulation, ensuring efficient and error-free application development.

Section 5: Industry-specific Solutions

5.1 Manufacturing

Pou PLCs find extensive use in manufacturing industries, where they control assembly lines, material handling systems, and robotic operations. Their ability to integrate with enterprise systems enables efficient production planning, inventory management, and quality control.

5.2 Energy Management

In the field of energy management, Pou PLCs assist in the monitoring and control of power distribution, load balancing, and renewable energy systems. They enable real-time energy consumption analysis, facilitating effective energy-saving measures.

5.3 Building Automation

Pou PLCs are also employed in building automation, where they regulate HVAC (Heating, Ventilation, and Air Conditioning), lighting control, access control, and security systems. Their integration with sensors and actuators enables intelligent and energy-efficient building management.

Conclusion

Pou PLCs have established themselves as a reliable and versatile solution for industrial automation and control. With their robust construction, versatile communication capabilities, and scalable design, Pou PLCs can handle complex tasks in diverse industrial environments. By providing superior performance, flexibility, and ease of programming, Pou PLCs contribute significantly to the field of electrical engineering and automation, enabling enhanced productivity and efficiency in various application areas.

________________________________________________________________________

免责声明:本文非官方发布,内容真实性请注意甄别,文章内容仅供参考。本站不对内容真实性负责,请悉知!本站不对内容真实性负责,请悉知!。我们专注于汇川技术产品培训,官网https://shicaopai.com |

共30章节527课时

共30章节527课时

共31章节522课时

共31章节522课时

共9章节44课时

共9章节44课时

共5章节63课时

共5章节63课时

共6章节52课时

共6章节52课时

共30章节527课时

共30章节527课时

共9章节44课时

共9章节44课时

共31章节522课时

共31章节522课时

共5章节63课时

共5章节63课时

共4章节36课时

共4章节36课时

共6章节52课时

共6章节52课时

共4章节29课时

共4章节29课时

共3章节30课时

共3章节30课时

共3章节25课时

共3章节25课时

共3章节24课时

共3章节24课时

共30章节527课时

共30章节527课时

共9章节44课时

共9章节44课时

共31章节522课时

共31章节522课时

共5章节63课时

共5章节63课时

共4章节36课时

共4章节36课时

共6章节52课时

共6章节52课时

共4章节29课时

共4章节29课时

共3章节30课时

共3章节30课时

共3章节25课时

共3章节25课时

共3章节24课时

共3章节24课时